XRB100N100 Monoblock® Industrial X-Ray Generators

- Integrated HV Supply, Filament Supply, X-Ray Tube, Beam Port and Control Electronics

- Compact & Lightweight

- Universal input, Power Factor Corrected with Internal EMI Filter

- Can be Mounted in Any Physical Orientation

- Analog Control Interface and Standard RS-232 Digital Interface

*Note: All specifications are subject to change without notice. Please consult the English PDF version of this datasheet for the most up-to-date revision.

100kV, 100W X-Ray Source

Spellman’s XRB100N100 Monoblock® X-Ray source is designed for OEM applications powering its internal X-Ray tube up to 100kV at 100W. Features like universal input, small package size and a standard analog and RS-232 digital interface simplify integrating this Monoblock® into your X-Ray system. Proprietary emission control circuitry provides excellent regulation of X-Ray tube current, along with outstanding stability performance.

Typical applications:

- X-Ray Scanning: Food Inspection

- Fill Level Confirmation

- Security Applications

Specifications

(Ref. 128072-001 REV. L)

X-Ray Characteristics:

Tube Type: Stationary anode, tungsten target

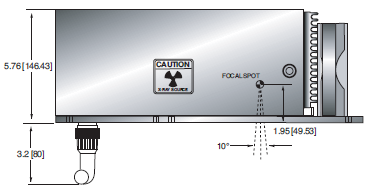

Focal Spot: 0.5mm (IEC 336)

Beam Filter: Lexan: 3.2mm

Oil: 10mm ±0.1mm

Glass: 1.8mm max

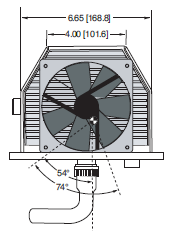

Beam Geometry: Symmetrical fan 74° x 10° ±1°

Input Voltage:

Power factor corrected input 0.98, 100-240Vac ±10% 50/60Hz, 2A, maximum

X-Ray Tube Voltage:

Nominal X-Ray tube voltage is adjustable between 40kV to 100kV

X-Ray Tube Current:

100uA to 1mA over specified tube voltage range

X-Ray Tube Power:

100W, maximum continuous

Voltage Regulation:

Line: ±0.1% of maximum output voltage over a ±10% change of nominal input line voltage

Load: ±0.1% of maximum rated voltage for 100uA to 1mA load change

Voltage Accuracy:

Voltage measured across the X-Ray tube is within ±2% of the programmed value

Voltage Risetime:

Ramp time shall be 1 second from 10% to 90% of maximum rated output voltage

Voltage Overshoot:

5% of maximum voltage, to return within 2.5% of maximum voltage in less than 50ms

Voltage Ripple:

0.5% peak to peak of maximum voltage for frequencies ≤ 1kHz

Emission Current Parameters Current Regulation:

Line: ±0.5% of rated output current over a ±10% change of nominal input line voltage

Load: ±0.5% of rated output current for a change from 50% to 100% of rated output voltage

Current Accuracy:

Current measured through the X-Ray tube is within ±1% of the programmed value

Current Risetime:

Ramp time shall be 1 second from 10% to 90% of maximum rated current

Arc Intervention:

3 arcs in 10 seconds with a 200ms quench = Shutdown

Filament Configuration:

Internal high frequency AC filament drive with closed loop filament emission control

Analog Interface:

Ground referenced 0 to 9Vdc for all programming and monitoring signals. Relay contacts and open collector signals for other signals. See analog interface connector pin out table.

Digital Interface:

Jumpers are needed to be configured and the digital interface cable installed to enable the RS-232 interface.

Control Software:

A demo GUI is available for engineering evaluations.

Interlock/Signals:

A hardware interlock functions in both analog and digital programming modes. The hardware X-Ray Enable signal only functions in analog programming mode.

Operating Temperature:

0°C to +40°C

Storage Temperature:

-40°C to +70°C

Humidity:

10% to 95% relative humidity, non-condensing

Cooling:

Forced air and natural convection augmented by customer provided external cooling fan to maintain oil temperature below 55°C.

Input Line Connector:

3 pin, Phoenix Contact 1829167, SHV part number 105725-219. Mating connector Phoenix Contact #1805990, SHV part number 105808-475 provided with unit.

Analog Interface Connector:

15 pin D connector, male

Digital Interface Connector:

9 pin D connector, female

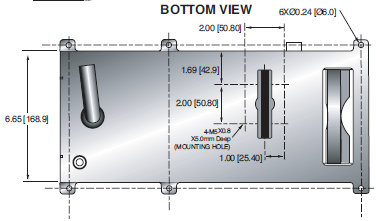

Grounding Point:

M4 ground stud provided on chassis

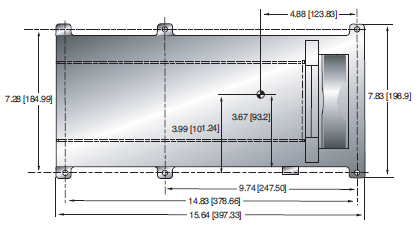

Dimensions:

See page 3 of 3

Weight:

55lbs (25kg)

Orientation:

Can be mounted in any orientation.

X-Ray Leakage:

Not to be greater than 0.5mR/hr at 5cm outside the external surface.

AC LINE POWER CONNECTOR— J1 THREE POSITION PHOENIX CONTACT

| Pin | Signal |

|---|---|

| 1 | Earth Ground |

| 2 | Line |

| 3 | Neutral |

Mating connector provided with unit

RS-232 DIGITAL INTERFACE— J3 9 PIN FEMALE D CONNECTOR

| Pin | Signal | Parameters |

|---|---|---|

| 1 | N/C | No Connection |

| 2 | TD | Transmit Data |

| 3 | RD | Receive Data |

| 4 | N/C | No Connection |

| 5 | SGND | Signal Ground |

| 6 | NC | No Connection |

| 7 | NC | No Connection |

| 8 | NC | No Connection |

| 9 | NC | No Connection |

XRB ANALOGINTERFACE— J2 15 PIN MALE D CONNECTOR

| Pin | Signal | Parameters |

|---|---|---|

| 1 | Power Supply Fault Output PARAMETERS |

Open collector, 35V @ 10mA max. high = no fault |

| 2 | mA Program Input | 0 to 9.00Vdc = 0 to 100% rated output, Zin =10MΩ |

| 3 | kV Program Input | 0 to 9.00Vdc = 0 to 100% rated output, Zin =10MΩ |

| 4 | X-Ray On Lamp Relay Output | Common, dry contacts, 30Vdc @ 1A, max |

| 5 | X-Ray On Lamp Relay Output | Normally open, X-Ray ON = closed |

| 6 | mA Monitor Output | 0 to 9Vdc = 0 to 100% rated output, Zout =10kΩ |

| 7 | X-Ray On Lamp Relay Output | Normally closed, X-Ray ON = open |

| 8 | kV Monitor Output | 0 to 9.00Vdc = 0 to 100% rated output, Zout =10kΩ |

| 9 | Signal Ground | Ground |

| 10 | Signal Ground | Ground |

| 11 | HV Interlock Return Input | Connect to Pin 12 to close HV interlock |

| 12 | HV Interlock Output | +15Vdc @ open, 5mA when connected to pin 11 |

| 13 | X-Ray Enable Output | +15Vdc @ open, 5mA when connected to pin 15 |

| 14 | X-Ray Status Output | Open collector, 35V @ 10mA max high = X-Ray OFF |

| 15 | X-Ray Enable Return Input | Connect to pin 13 to enable X-Ray generation |

XRB ANALOGINTERFACE— J2 15 PIN MALE D CONNECTOR

| Indicator | Signal Name | Condition Illuminated When... |

|---|---|---|

| LED 1 | OV | High kV occurs |

| LED 2 | UV | Low kV occurs |

| LED 3 | UC | Low mA occurs |

| LED 4 | OC | High mA occurs |

| LED 5 | ARC FLT | Arc fault occurs |

| LED 6 | OT | Over temperature occurs |

| LED 7 | X-RAY ON | X-Rays are enabled |

| LED 8 | PWR | Power is ON |

Tables & Diagrams

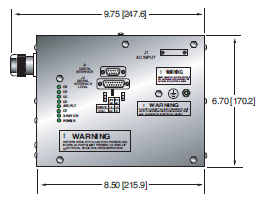

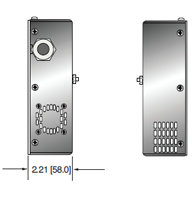

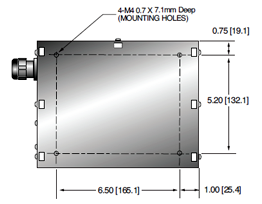

DIMENSIONS: in.[mm]

X-RAY GENERATOR

FRONT VIEW

TOP VIEW

SIDE VIEW

BOTTOM VIEW

CONTROL UNIT

FRONT VIEW

TOP VIEW

SIDE VIEW

BOTTOM VIEW

Frequently Asked Questions

Why Is Oil Insulation Used?

Do I Need to Ensure My Monoblock® Stays Cool? Why?

How Often Do I Need to Season My Monoblock® X-Ray Source? Why?

Application Notes AN-12 – The Benefit of Using a Current Source to Power X-Ray Tube Filament Circuits