Industrial CT / 3D Imaging

Industrial computed tomography (CT) is used to produce 3D representations of solid objects to non destructively inspect mission critical parts and complex objects. Common applications include:

- Void Analysis in Plastic or Metal Components

- Flaw Detection

- Failure Analysis

- Metrology

- Assembly Analysis

- Part to CAD/Part to Part Comparison or Reverse Engineering

Spellman has a large selection of X-Ray generators and sources to choose from. Low to high density materials analysis benefits from Spellmans low ripple, high stability X-Ray generator and source platforms that improve image quality and throughput in Industrial CT imaging applications. Spellman's solutions are reliable and cost effective with industry leading warranties available. CE/UL compliant, superior performance, flexible standard products, low cost of ownership and ease of integration are the features that most Spellman customers see value in.

- Output Voltage 60kV - 140kV

- Output Power 32kW / 42kW / 50kW models with same dimensions and interface for ultimate flexibility

- Compact gantry mounting saves space, time and weight

- 16/32 slice with 0.5 rotation covering all clinical needs

- Optional grid box for deflection or cut off provide dose control and improves image quality

- Integrated fully programmable starter

- Compatible with all industry standard X-Ray tubes

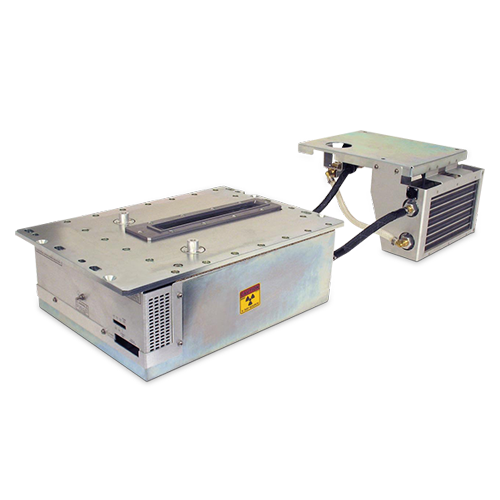

- Output Voltage up to 160kV

- Output Power 688W

- Integrated HV Supply, Filament Supply, X-Ray Tube, Beam Port and Control Electronics

- Compact & LIghtweight

- Power Factor Corrected

- Can be Mounted in Any Physical Orientation

- Standard RS-232 Digital Interface

- Output Voltage up to 160kV

- Output Power 400W

- Integrated HV Supply, Filament Supply, X-Ray Tube, Beam Port and Control Electronics

- Compact & Lightweight

- Can be Mounted in Any Physical Orientation

- Analog Monitoring and Standard RS-232 Digital Interface

- Integrated X-Ray Tube and Control Electronics in One Compact Assembly

- Standard RS-232 Digital Interface Offers Access to Diagnostics and Operating Logs

- Standard Windows Test GUI

- 7 Micron Focal Spot for Narrow Beam

- 8 Micron Focal Spot for Wide Beam

- 10mm/14mm Spot to Window Spacing Provides High Geometric Magnification