SLS СЕРИЯ

- Выходное напряжение 160–360 кВ

- Низкий уровень пульсаций

- Высокая стабильность

- Защита от сверхтока, перенапряжения и дуги

- Обнаружение дуги

- Малый вес и компактность

- Возможность изготовления по спецификациям заказчика

* Примечание: Все спецификации могут быть изменены без предварительного уведомления. Пожалуйста, ознакомьтесь с английской версией PDF этой спецификации для получения последней актуальной информации об оборудовании.

2000W High Voltage Power Supplies

Высоковольтные источники питания серии SLS обеспечивают мощность до 2000 Вт при выходном напряжении в диапазоне от 160 до 360 кВ. В этих источниках используются резонансные инверторы с патентованными органами управления, обеспечивающими высокую надежность в жестких условиях эксплуатации. Блок высоковольтного умножителя имеет гибридную конструкцию, в которой сочетается надежная герметизация и наличие воздуха, что снижает общий размер устройства. Умножитель, состоящий из плотно прилегающих пластин с напряжением 20 кВ, позволяет гибко формировать блоки питания для различных конфигураций выходных параметров.

Типовые применения:

- Ионная имплантация

- Ускорители частиц

- Электронные пушки

Технические характеристики

(Ref. 128016-001 REV. N)

Options

eSL Ethernet Connectivity/VFD Front Panel

Input Voltage:

Standard: 220Vac ±10%, 50/60Hz @ 8A/phase, three phase

Optional: 200Vac ±10%, 50/60Hz @ 8.9A/phase, three phase

Output Voltage Range:

Models available from 160kV to 360kV and up

to 2000W. Each model is available with positive

or negative polarity outputs.

Voltage Regulation:

Better than 0.05% for specified line variations

and load variations.

Ripple:

0.1% p-p of maximum output voltage.

Remote Voltage Control:

0 to +10V for 0 to maximum voltage. Accuracy and

repeatability: 1% of maximum rating.

Remote Current Control:

0 to +10V for 0 to maximum voltage. Accuracy and

repeatability: 1% of maximum rating.

Voltage Monitor:

0 to 10V equivalent to rated voltage. Accuracy, 1% reading.

Current Monitor:

0 to 10V equivalent to rated current. Accuracy, 1% reading.

Stability:

0.05% per hour after 1/2 hour warm-up.

0.05% per 8 hours.

Slow Start:

Slow start times: 6 seconds standard.

Temperature Coefficient:

0.01% per degrees C.

Protection:

Overcurrent, Overvoltage, Arc protection, Overtemperature.

Arc Detect:

If 8 arcs occur in a 10 second, non-synchronous time window, the supply reverts to the Power Down Mode with an ARC fault displayed on the front panel default diagnostic display.

Environmental:

Temperature Range:

Operating: 0°C to 40°C

Storage: -20°C to 85°C

Humidity:

10% to 70%, non-condensing.

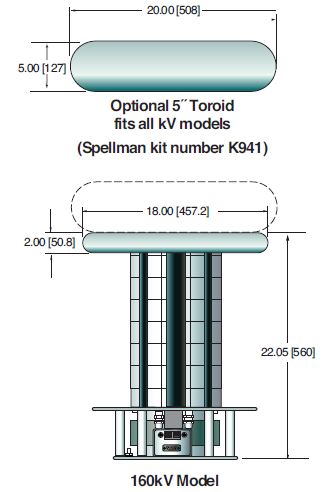

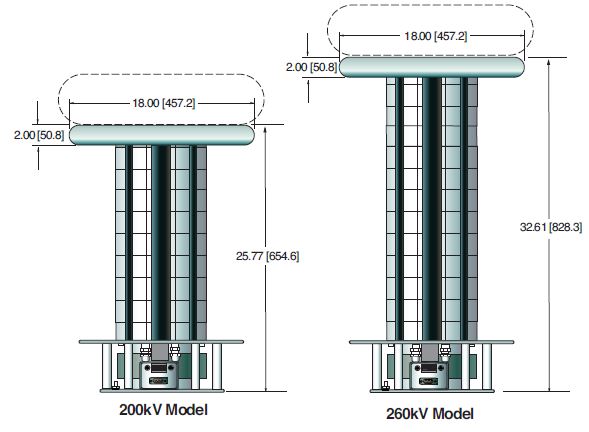

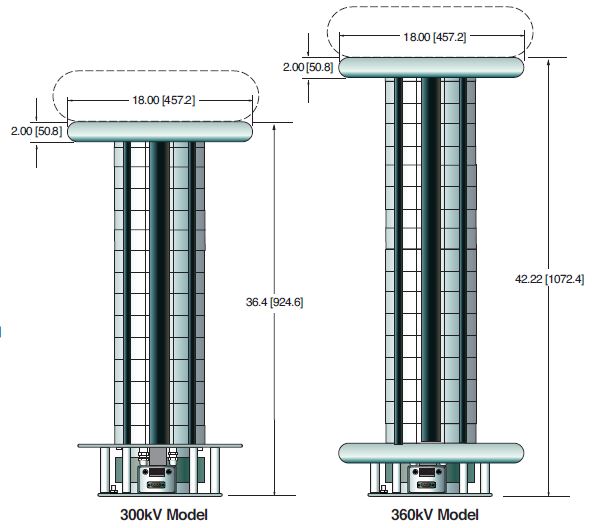

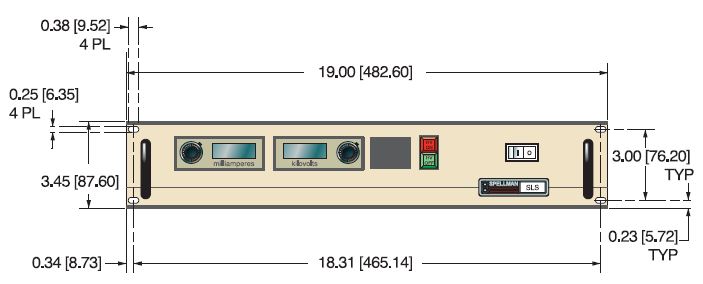

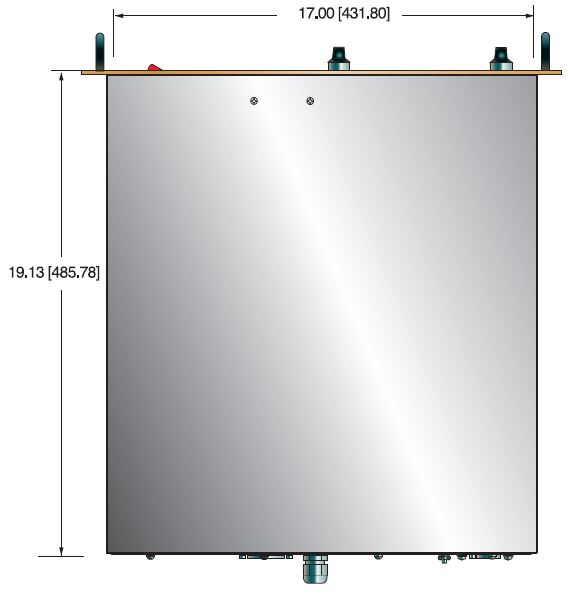

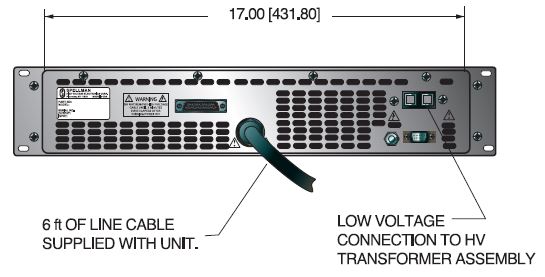

Dimensions:

Inverter Driver Chassis:

3.50”(2U)H x 19.0”W x 19.0”D (8.9cm x 48.3cm x 48.3cm)

Multiplier Unit:

Depends on model specified.

Distance from Stack to Driver:

2.5 meters ±0.1 meter maximum.

Signal Connector:

25 pin, male D connector, J3.

Metering:

Front panel, 3.5 digit, digital voltage and current meters.

Front Panel Controls:

Voltage and current are continuously adjustable by ten-turn potentiometers with lockable counting dials, ON/OFF circuit breaker/lamp, high voltage ON switch/indicator and high voltage OFF switch/indicator.

Front Panel Status Indicators:

Voltage Control Mode Overcurrent

Current Control Mode Overvoltage

Interlock Open Arc

Interlock Closed Regulation Error

High Voltage Inhibit Overtemperature

Overpower (optional)

Regulatory Approvals:

RoHS compliant.

Corona Dome Terminations:

The SLS Series of “stack” configured high voltage power supplies come in a various output voltages and different physical configurations. Appropriate corona relief is required for these units to operate at maximum output voltage. Frequently users will provide the corona relief needed so Spellman will provide stack assemblies that by themselves will not be able to operate at maximum output voltage corona free. Please be certain to discuss your requirements with Spellman to be assured you get a stack assembly in the physical configuration you require for your application. The optional K941 Toroid (5˝ x 20˝) should be considered if customer corona relief will not be provided.

360kV Stack Shown with opptional K941 Toroid

Electronic Component (Power Source)

SLS series is intended for installation as a component of a system. It is designed to meet CE standards, with conditions of acceptance often being: customer provided enclosure mounting, EMC filtering, and appropriate protection, and isolation devices. The SLS series is not intended to be operated by end users as a stand-alone device. The SLS series power supply can only be fully assessed when installed within a system, and as a component part within that system.

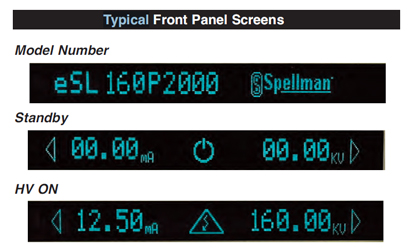

eSL Option

The eSL Option provides a vacuum fluorescent front panel display and Ethernet connectivity. Both the 1U (1.75”) and 2U (3.5”) SL product offerings are available with the eSL Option. Using the front panel local controls the main menu has the following features:

Local/Remote Control

Allows operation from either the local front panel or remotely via the Ethernet Category 5 connector.

Features Menu

Allows control over Adjustable Overload Trip and Slow Start features.

Tutorial Menu

Provides information on how to use the local front panel interface.

Diagnostics Menu

Provides information on the revisions of the hardware, firmware and IP address. Additionally the Diagnostics Menu provides information on the status of the internal low voltage housekeeping power supply voltages.

eSL Option power supplies can still be fully controlled via the SL’s comprehensive remote analog interface, so these units are fully backwards compatible with standard SL power supplies.

SLS SELECTION TABLE

| Maximum Rating | Model Number | |

|---|---|---|

| kV | mA | |

| 160 | 12.5 | SLS160*2000 |

| 200 | 10.0 | SLS200*2000 |

| 260 | 7.7 | SLS260*2000 |

| 300 | 6.6 | SLS300*2000 |

| 360 | 5.5 | SLS360*2000 |

*Specify “P” for positive polarity or “N” for negative polarity Other combinations of voltage and current are available.

SLS I/O INTERFACE CONNECTOR 25 PIN

| Pin | Signal |

|---|---|

| 1 | Power Supply Common |

| 2 | External Inhibit |

| 3 | External Interlock |

| 4 | External Interlock Return |

| 5 | Current Monitor |

| 6 | Voltage Monitor |

| 7 | +10V Reference |

| 8 | Remote Current Program In |

| 9 | Local Current Program Out |

| 10 | Remote Voltage Program In |

| 11 | Local Voltage Program Out |

| 12 | Optional EFR (common) |

| 13 | Optional EFR (normally closed) |

| 14 | Local HV OFF Out |

| 15 | HV OFF |

| 16 | Remote HV ON |

| 17 | Remote HV OFF Indicator |

| 18 | Remote HV ON Indicator |

| 19 | Remote Voltage Mode |

| 20 | Remote Current Mode |

| 21 | Spare |

| 22 | Remote PS Fault |

| 23 | +15V Output |

| 24 | Power Supply Common |

| 25 | Shield Return |

Таблицы и диаграммы

DIMENSIONS: in.[mm]

FRONT VIEW

TOP VIEW

BACK VIEW

Frequently Asked Questions

What Is a Safe Level of High Voltage?

What Is an “External Interlock”?

Where Can I Obtain Information on High Voltage Safety Practices?

What is a Stack Type High Voltage Power Supply?

Why Are Corona Rings/Toroids/Balls Used on High Voltage Power Supplies?

Why Is Arcing an Issue for a High Voltage Power Supply?

Application Notes AN-14 – The Limits of Front Panel Digital Meters

Application Notes AN-15 – 3.5 And 4.5 Digit Meter Displays Explained

Application Notes AN-18 – Current Loop/Arc Detection Circuitry

Application Notes AN-23 – SL HV Off and HV on Circuitry Explained