XRBHR MONOBLOCK® X線ジェネレーター

- コンパクトで軽量

- ユニバーサル入力、力率改善回路

- あらゆる向きに取り付け可能

- アナログモニターインターフェース、標準RS-232デジタルインターフェースとイーサネット

- Data Logging and Firmware Controlled X-Ray Tube Seasoning

*注意:すべての仕様は予告なしに変更されることがあります。最新の情報は 英語版のデータシート をご参照ください。

100W, 210W, 350W and 500W X-Ray Source

スペルマンのXRBHR(HR:高信頼性)シリーズのMonoblock®X線源は、100W、210W、350W、および500Wの出力レベルで、80kVおよび100kVのバイポーラX線管を用いており、OEMアプリケーション向けに設計されています。ユニバーサル入力、コンパクトなパッケージサイズ、標準RS-232デジタルインターフェースなどの機能により、お客様のX線システムにXRBHR モデルを簡単に統合できます。各XRBHRモデルは、ファン形(標準)またはコーン形(オプション)のビーム形状がございます。独自のエミッション制御回路は、非常に安定した性能でX線管電流を制御します。XRBHRシリーズは、長いフィールド寿命を実現するよう設計されており、3年間の保証が付いています。

代表的なアプリケーション

食品検査装置、充填レベル検査装置、セキュリティスキャンシステム、産業用NDTシステム、厚さ/メッキ測定システム。

Specifications

(Ref. 128132-001 REV. V)

Options:

CB Cone Beam

.5mm .5mm focal spot X-Ray tube

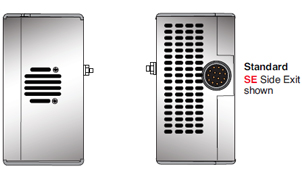

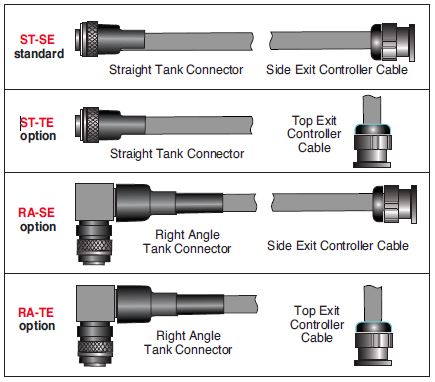

ST-TE See Cable Options

RA-SE See Cable Options

RA-TE See Cable Options

SPECIFICATIONS

X-Ray Characteristics:

Focal Spot: 0.8mm (IEC 336)

0.5mm (IEC 336) optional

Beam Filter:

Ultem: 1.50mm ±0.15mm

Oil: 9.0mm ±0.25mm

Glass: 1.7mm ±0.2mm

Be: 0.8mm

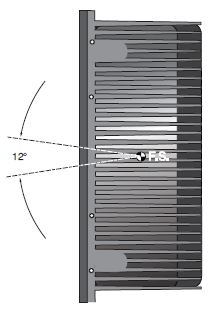

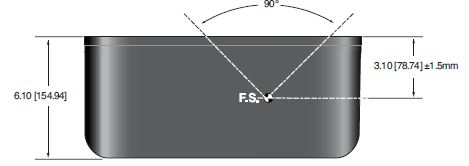

Beam Geometry:

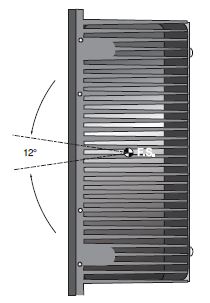

Fan: Standard. The beam angular coverage will be 80° with the beam plane perpendicular to the X-Ray tube axis and 12° wide (with a 2° tolerance)

Cone: Optional. 40° cone beam (with a 2° tolerance)

Input Voltage:

100-240Vac, ±10%, 50/60 Hertz, .98 power factor

Input Current:

100W @ 2A

210W @ 4A

350W @ 6A

500W @ 8A

X-Ray Tube Voltage:

See table

X-Ray Tube Current:

See table

X-Ray Tube Power:

See table

Operating Temperature:

0°C to +40°C

Storage Temperature:

-40°C to +70°C

Humidity:

10% to 95% relative humidity, non-condensing

Cooling:

0.5% peak to peak of maximum voltage for frequencies ≤1kHz

Emission Current Parameters

Current Regulation:

Line: ±0.05% of rated output current over a ±10% change of nominal input line voltage

Load: ±0.1% of rated output current for a change from 50% to 100% of rated output voltage

Current Accuracy:

Current measured through the X-Ray tube is within ±2% of the programmed value

Current Risetime:

Standard: Ramp time shall be <500ms from 10% to 90% of maximum rated current

Arc Intervention:

4 arcs in 10 seconds with a 100ms quench/100ms re-ramp = Shutdown

Filament Configuration:

Internal AC filament drive with closed loop filament emission control

Analog Interface:

Ground referenced 0 to 9Vdc for all monitoring signals.

Relay contacts and open collector signals for other signals. See analog interface connector pin out table.

Digital Interface:

The RS-232 interface allows for programming of kV, mA output and X-Ray enable. Provides monitoring for kV, mA output and oil temperature. Tolerance 3%. (with an additional 5μA offset at ≤10% mA programming)

Operating Temperature:

0°C to +40°C

Storage Temperature:

-40°C to +70°C

Humidity:

10% to 95% relative humidity, non-condensing

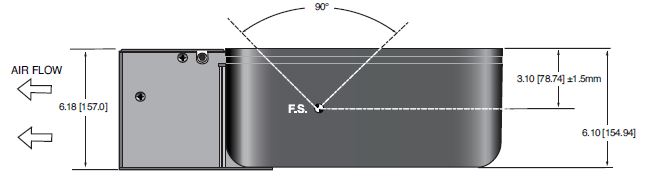

Cooling:

X-Ray Tank:

100W: Convection/customer supplied forced air so tank is < 55˚C

210W: Externally powered forced air cooling, 24Vdc @ 2A

350W: Externally powered forced air cooling with oil pump and heat exchanger, 24Vdc @ 5A

500W: Externally powered forced air cooling with oil pump and heat exchanger, 24Vdc @ 5A

Controller: Forced air via internal fan.

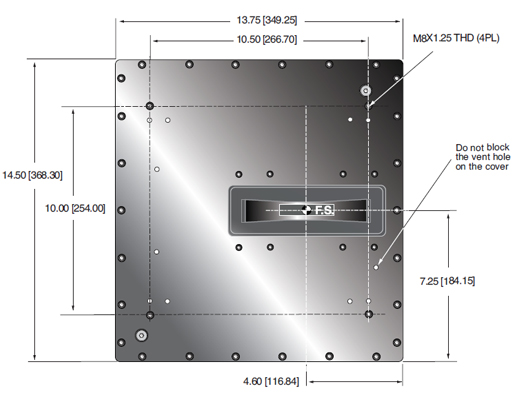

Grounding Point:

M5 ground female thread on tank

M5 ground stud on control chassis provided

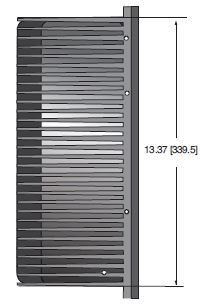

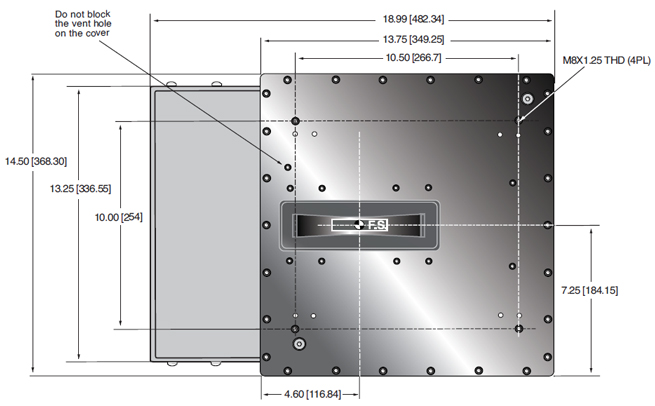

Dimensions:

X-Ray Tank: See drawings

100W/210W Controller: See drawings

350W/500W Controller: See drawings

Weight:

X-Ray Tank:

100W @ 75 lbs. (34kg)

210W @ 75lbs. (34kg)

350W @ 81.5lbs. (37kg)

500W @ 81.5lbs. (37kgs)

Orientation:

Can be mounted in any orientation.

X-Ray Leakage:

Not to be greater than 0.5mR/hr at 5cm outside the external surface.

Regulatory Approvals:

Compliant to EEC EMC Directive. Compliant to EEC Low Voltage Directive. UL/CUL recognized file E235530

MODEL SELECTION TABLE

| Model | Maximum Voltage | Maximum Current | Maximum Power |

|---|---|---|---|

| XRB80PN210HR | 80kV | 5.25mA | 210 watts |

| XRB80PN350HR | 80kV | 8mA | 350 watts |

| XRB80PN500HR | 80kV | 8mA | 500 watts |

| XRB100PN100HR | 100kV | 2mA | 100 watts |

| XRB100PN210HR | 100kV | 4.2mA | 210 watts |

| XRB100PN350HR | 100kV | 7mA | 350 watts |

| XRB100PN500HR | 100kV | 8mA | 500 watts |

LED INDICATORS for 100W and 200W Units

| INDICATOR | SIGNAL | CONDITION Illuminated When... | LED COLOR |

|---|---|---|---|

| 1 | OV Error 6 | High kV occurs | Red |

| 2 | UV Error 5 | Low kV occurs | Red |

| 3 | UC Error 4 | Low mA occurs | Red |

| 4 | Power On | AC input power is present | Green |

| 5 | OC Error 3 | High mA occurs | Red |

| 6 | ARC Error 2 | Arc fault occurs | Red |

| 7 | OT Error 1 | Over temperature occurs | Red |

| 8 | X-Ray On | X-Rays are being generated | Green |

LED INDICATORS for 350W and 500W Units

| INDICATOR | SIGNAL | CONDITION Illuminated When... | LED COLOR |

|---|---|---|---|

| 1 | OV Error 6 | High kV occurs | Red |

| 2 | UV Error 5 | Low kV occurs | Red |

| 3 | UC Error 4 | Low mA occurs | Red |

| 4 | OC Error 3 | High mA occurs | Red |

| 5 | ARC Error 2 | Arc fault occurs | Red |

| 6 | OT Error 1 | Over temperature occurs | Red |

| 7 | X-Ray On | X-Rays are being generated | Green |

| 8 | Power On | AC input power is present | Green |

| SMART XRB |

||

|---|---|---|

|

The XRBHR has two new digital features: data logging and firmware controlled seasoning. Data Logging: FAULT EVENTS The XRBHR stores data 620ms before the event, the event itself and for 620ms after the event. Data is recorded every 20ms (62 samples total) showing: We also log non-fault events, these are changes in set points or state of the unit. NON FAULT EVENTS Fault event data is actual graphical data. Non fault event data is just stored as event type, data and timestamp. We also have a preventative maintenance fault, which throws a non-shutdown fault if the X-Ray tube has been factory Firmware Controlled Seasoning: |

Power and Interface Connections for 100W and 210W Units

AC Input—6 PIN MOLEX 09-50-8061

| PIN | SIGNAL PARAMETERS | |

|---|---|---|

| 1 | AC Input (high) | 100-240Vac (high) |

| 2 | Pin Removed | N/C |

| 3 | AC Input (neutral) | 100-240Vac (neutral) |

| 4 | Pin Removed | N/C |

| 5 | N/C | N/C |

| 6 | N/C | N/C |

ANALOG INTERFACE—7 PIN MOLEX 09-50-8071

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | X-Ray Interlock Enable | Apply +24Vdc to enable interlock. Open/removal of +24Vdc will cause X-Ray generation to stop |

| 2 | X-Ray Interlock Enable Return | Ground reference for X-Ray Interlock |

| 3 | Pin removed | N/C |

| 4 | kV Monitor | 0-10Vdc = 0-100% rated output voltage. Zout = 10kΩ |

| 5 | Signal Ground | Signal Ground |

| 6 | mA Monitor | |

| 7 | X-Ray On | Open collector, High (Open) = No Fault, 35Vdc @10mA maximum |

RS-232 DIGITAL INTERFACE— 9 PIN MALE D CONNECTOR

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | N/C | N/C |

| 2 | Transmitted Data | Conforms to EIA RS-232-C |

| 3 | Received Data | Conforms to EIA RS-232-C |

| 4 | N/C | N/C |

| 5 | Signal Ground | Signal Ground |

| 6 | N/C | N/C |

| 7 | N/C | N/C |

| 8 | N/C | N/C |

| 9 | N/C | N/C |

ETHERNET DIGITAL INTERFACE— RJ45 8 PIN FEMALE CONNECTOR

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | TX + | Transmit Data + |

| 2 | TX - | Transmit Data - |

| 3 | RX + | Receive Data + |

| 4 | N/C | No Connection |

| 5 | N/C | No Connection |

| 6 | N/C | Receive Data - |

| 7 | N/C | No Connection |

| 8 | N/C | No Connection |

HV LAMP ON RELAY—3 PIN MOLEX 09-50-8031

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | Normally Closed dry contact | 50V max. Rated for 1 amp or less, 50mA nominal load |

| 2 | Common | 50V max. Rated for 1 amp or less, 50mA nominal load |

| 3 | Normally Open dry contact | 50V max. Rated for 1 amp or less, 50mA nominal load |

Power and Interface Connections for 350W and 500W Units

AC INPUT—3 PIN PHOENIX CONTACT 1858772

| PIN | SIGNAL PARAMETERS | |

|---|---|---|

| 1 | AC Input (high) | 100-240Vac (high) |

| 2 | Ground | Ground |

| 3 | AC Input (neutral) | 100-240Vac (neutral) |

DC INPUT FOR HEAT DISSIPATION UNIT—4 PIN AMP (210/350/500W) 206060-1

| PIN | SIGNAL | DESCRIPTION | PARAMETERS |

|---|---|---|---|

| 1 | 24Vdc | Fan/Pump Power | 24Vdc @ 5 amps |

| 2 | 24Vdc Return | Fan/Pump Power | 24Vdc @ 5 amps |

| 3 | N/C | No Connection | N/C |

| 4 | N/C | No Connection | N/C |

“It is critical to ensure that 24Vdc is supplied to pins 1 and 2”

ANALOG INTERFACE— 10 PIN PHOENIX CONTACT 1792605

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

|

1 |

X-Ray Interlock Enable | Apply +24Vdc to enable interlock. Open/removal of +24Vdc will cause X-Ray generation to stop. |

| 2 | X-Ray Interlock Enable Return | Ground reference for X-Ray Interlock. |

| 3 | Pin removed | N/C |

| 4 | kV Monitor | 0-10Vdc = 0-100% rated output voltage. Zout = 10kΩ |

| 5 | Signal Ground | Signal Ground |

| 6 | mA Monitor | 0-10Vdc = 0-100% rated output current. Zout =10kΩ |

| 7 | Fault Signal | Open collector, High (Open) = No Fault, 35Vdc @ 10mA maximum |

| 8 | HV ON Lamp Relay N/O | N/O dry contacts. 50 volts maximum. Rated for 1 amp or less, 50mA nominal load |

| 9 | HV ON Lamp Relay C | Common dry contacts. 50 volts maximum. Rated for 1 amp or less, 50mA nominal load |

| 10 | HV ON Lamp Relay N/C | N/C dry contacts. 50 volts maximum. Rated for 1 amp or less, 50mA nominal load |

RS-232 DIGITAL INTERFACE— 9 PIN MALE D CONNECTOR

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | N/C | N/C |

| 2 | Transmitted Data | Conforms to EIA RS-232-C |

| 3 | Received Data | Conforms to EIA RS-232-C |

| 4 | N/C | N/C |

| 5 | Signal Ground | Signal Ground |

| 6 | N/C | N/C |

| 7 | N/C | N/C |

| 8 | N/C | N/C |

| 9 | N/C | N/C |

ETHERNET DIGITAL INTERFACE— RJ45 8 PIN FEMALE CONNECTOR

| PIN | SIGNAL | PARAMETERS |

|---|---|---|

| 1 | TX + | Transmit Data + |

| 2 | TX - | Transmit Data - |

| 3 | RX + | Receive Data + |

| 4 | N/C | No Connection |

| 5 | N/C | No Connection |

| 6 | RX - | Receive Data - |

| 7 | N/C | No Connection |

| 8 | N/C | No Connection |

Tables & Diagrams

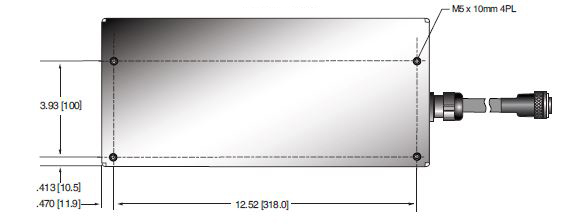

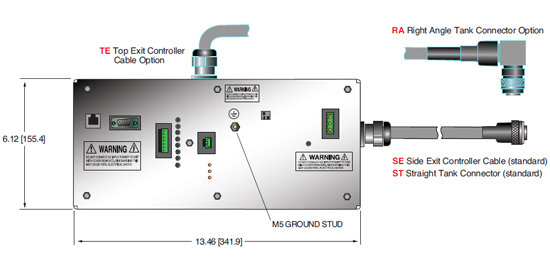

DIMENSIONS: in.[mm]

100/210W

CONTROL UNIT

FRONTVIEW

BOTTOM VIEW

REAR VIEW

SIDE VIEW

Cable Configurations

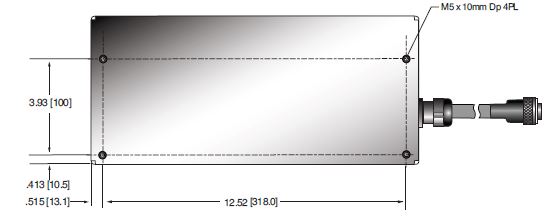

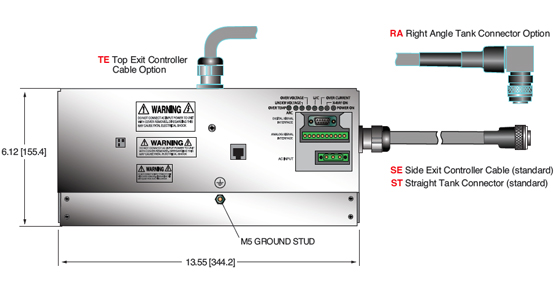

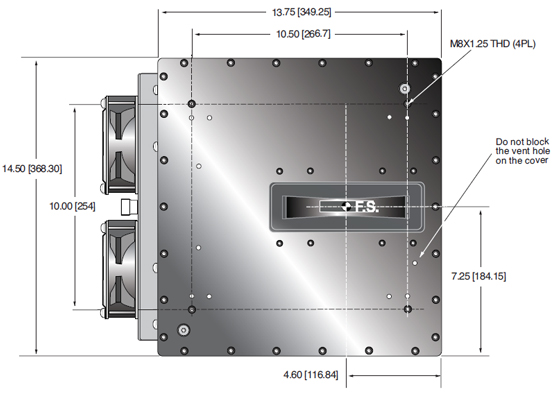

DIMENSIONS: in.[mm]

300/500W CONTROL UNIT

FRONT VIEW

BOTTOM VIEW

SIDE VIEW

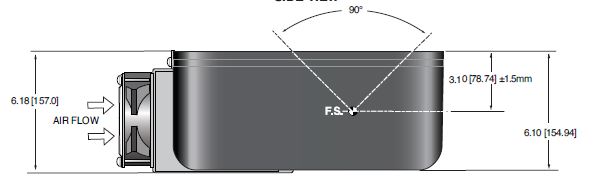

DIMENSIONS: in.[mm]

100W TANK

TOP VIEW

SIDE VIEW

BACK VIEW

FRONT VIEW

DIMENSIONS: in.[mm]

210W TANK

TOP VIEW

SIDE VIEW

BACK VIEW

FRONT VIEW

DIMENSIONS: in.[mm]

350/500W TANK

TOP VIEW

SIDE VIEW

BACK VIEW

FRONT VIEW

Frequently Asked Questions

Why Is Oil Insulation Used?

Do I Need to Ensure My Monoblock® Stays Cool? Why?

How Often Do I Need to Season My Monoblock® X-Ray Source? Why?

Application Notes AN-12 – The Benefit of Using a Current Source to Power X-Ray Tube Filament Circuits